Complete Production Solutions

NanoXSolar provides turnkey manufacturing equipment from Tier-1 suppliers, custom-designed and engineered for your production requirements. From pilot lines to full-scale GW production facilities.

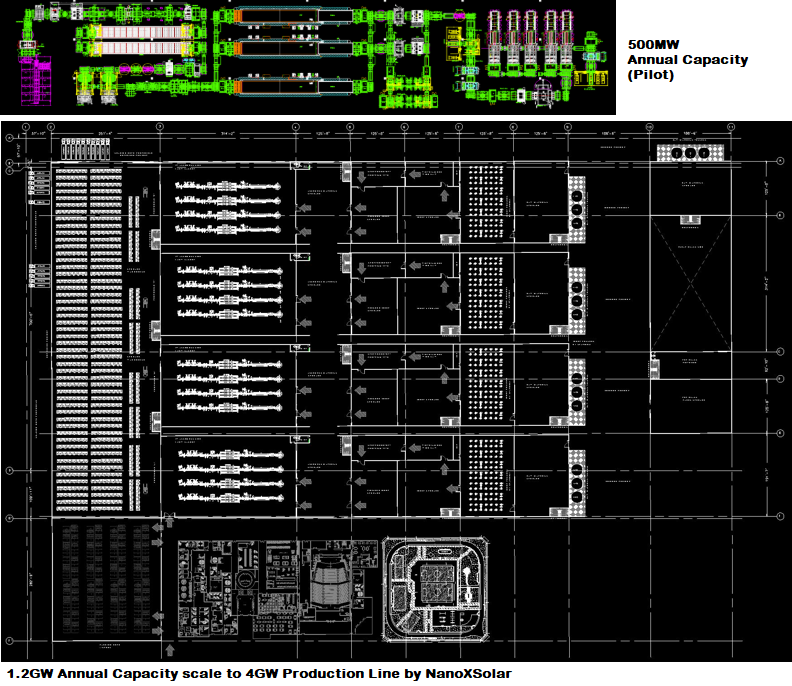

Solar PV Module Production Line

1.2 GW Capacity

Pilot Line 500MW starts at $7M + engineering & infrastructure

Complete PV Module Manufacturing Solution

Equipment Includes

- Cell testing and sorting equipment

- Automated stringing and tabbing

- Layup and lamination systems

- BIPV (Building Integrated PV) capability

- Framing and junction box installation

- Flash testing and QC systems

Specifications

- Tier-1 OEM equipment designed by NXS

- Scalable from pilot to full production

- Full training and installation support

- Compatible with mono and poly cells

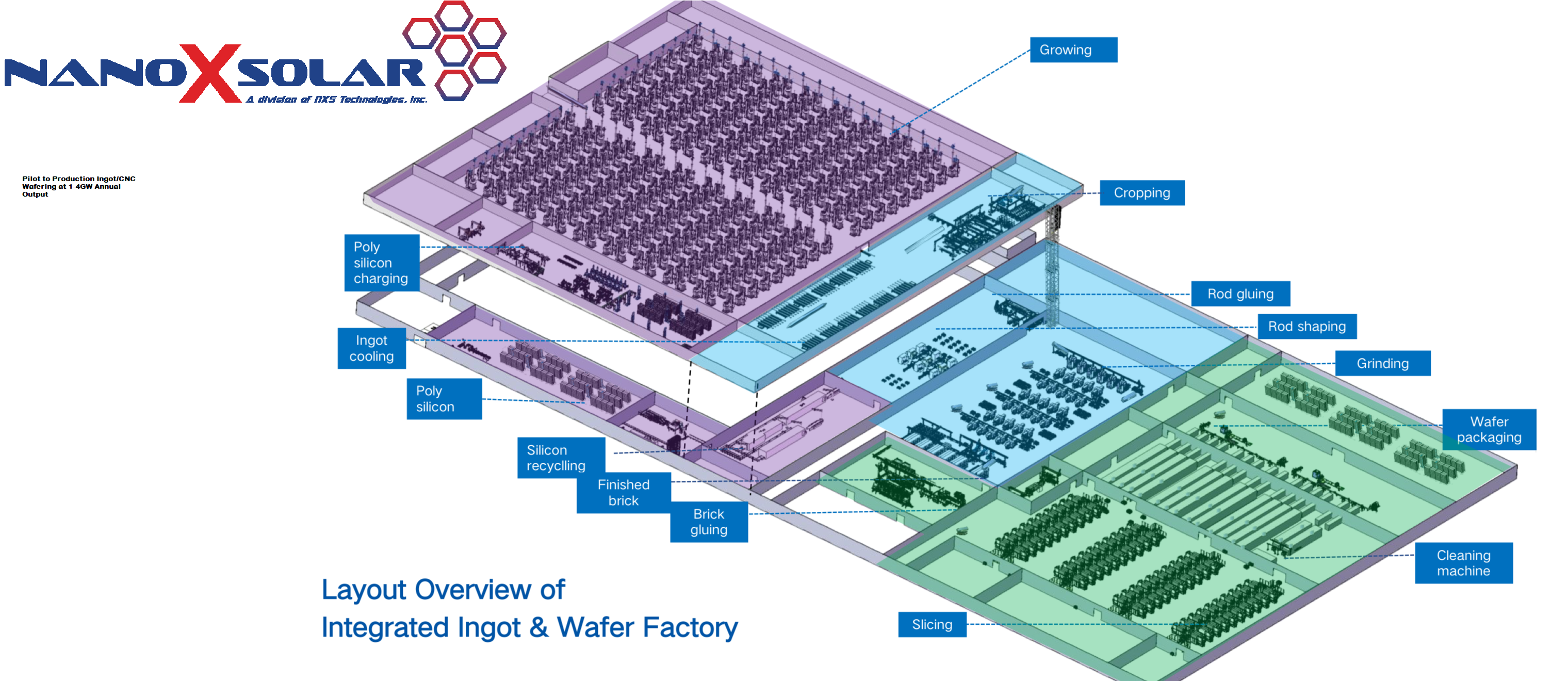

Ingot Growth, CNC Wafering & Battery Nano Si-Powders

Custom ingot growth for PV cell production wafering and nano-powders for battery cell.

Tier-1 Ingot Tooling Growth Line

Full-scale production line from Tier-1 PV tooling companies, OEM designed by NXS for custom ingot growth and battery cell manufacturing.

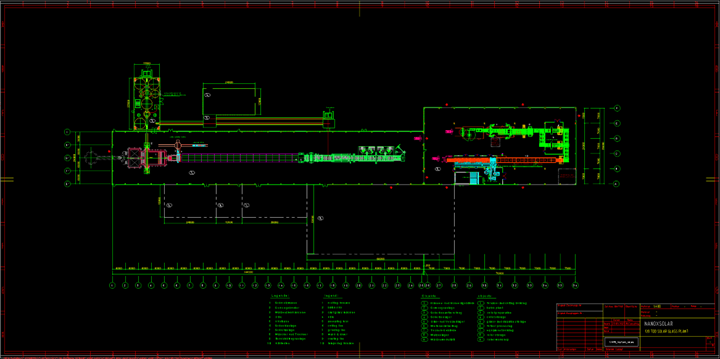

Download Design SpecificationsSolar Glass Oven Pilot Tooling Line

120 Tons Daily Production

From 200 tons of sand to PV & BIPV Diamond Plate Glass

AM3 Diamond Glass Production

We offer oolitic aragonite and SiO₂ quartz sand for AM3 Diamond Glass production. Nano-materials as raw feedstocks for aerospace-grade diamond glass, plate glass furnace, optics, mirror, cockpit, and sapphire glass applications.

Pilot Line Specifications

- 120 tons daily capacity

- Processes 200 tons of sand input

- Scalable to 2000 tons daily (SORG oven)

- Aerospace-grade output quality

Applications

- • Solar glass for PV modules

- • BIPV (Building Integrated PV) glass

- • Diamond-grade plate glass

- • Optical applications

- • Bulletproof glass

- • Aerospace cockpit glass

- • Sapphire glass substrates

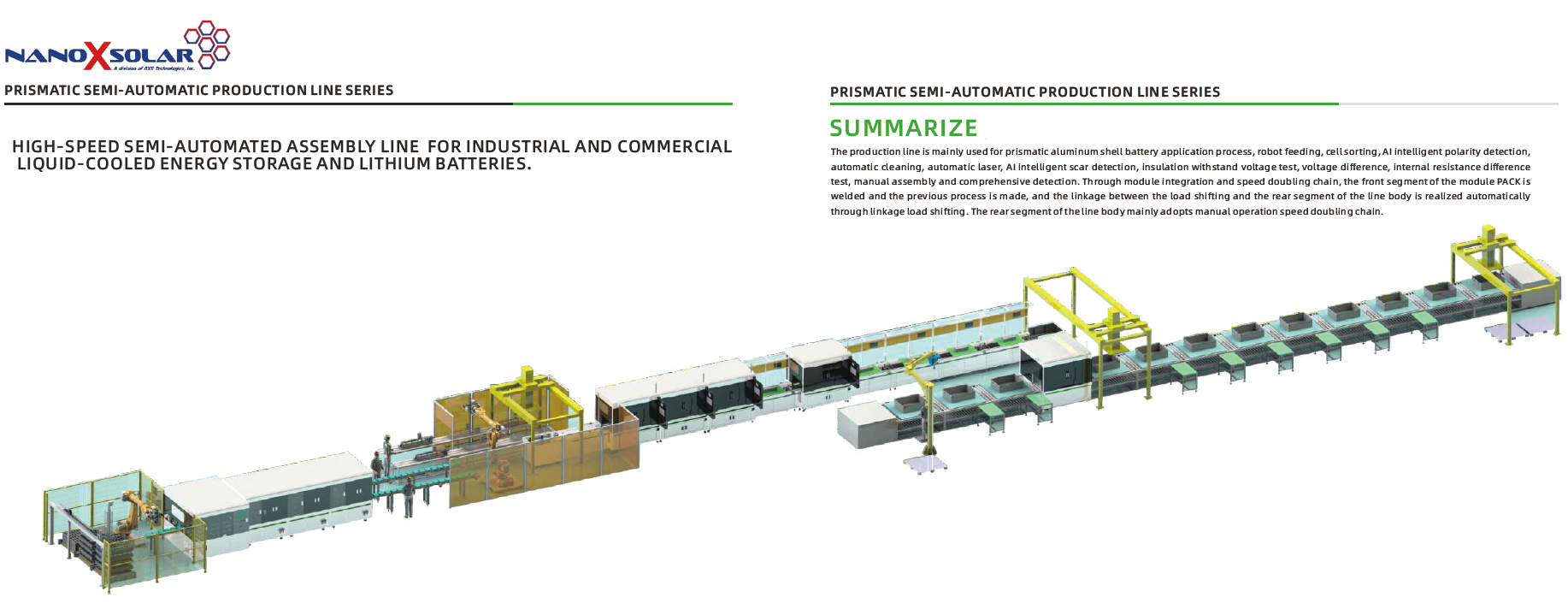

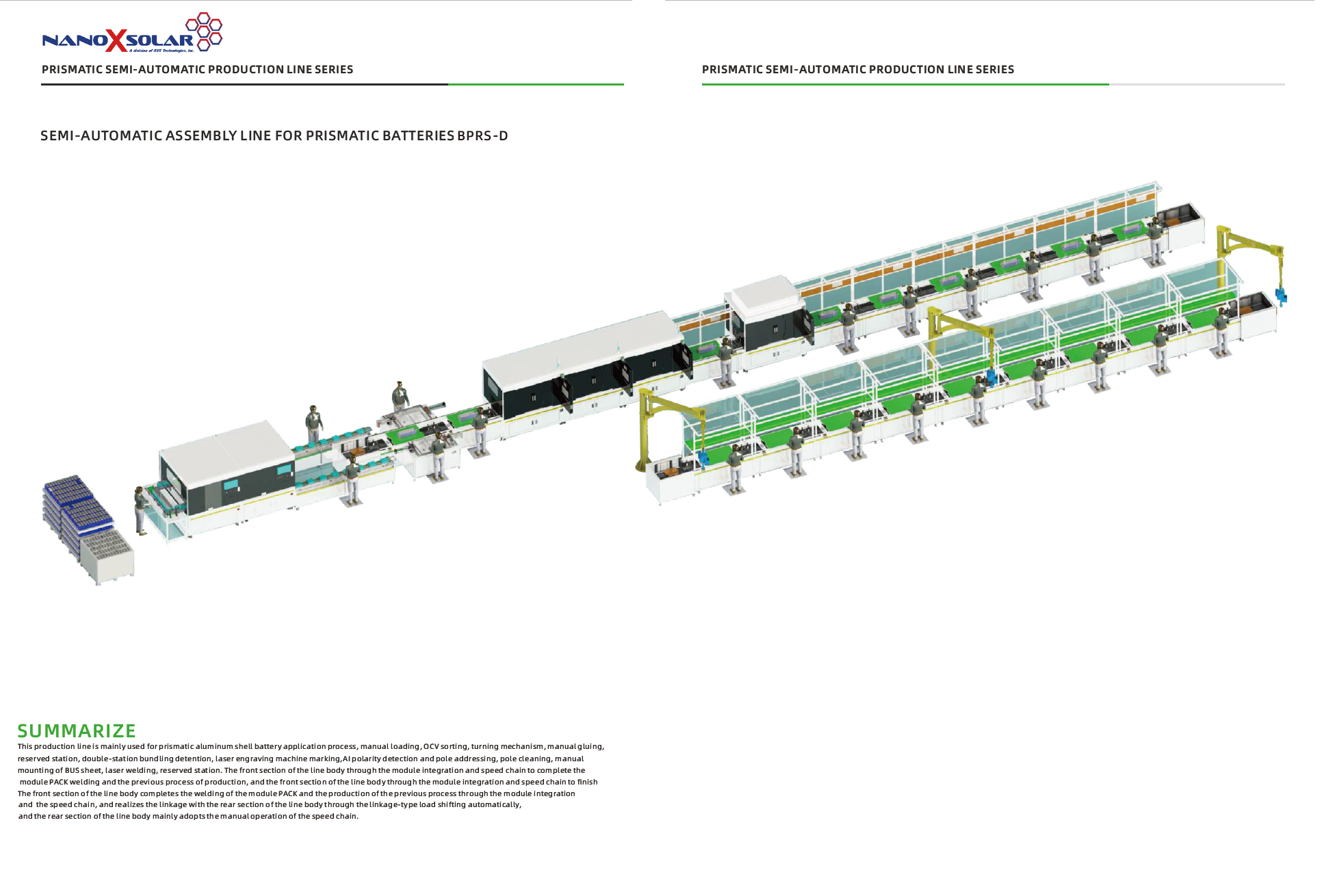

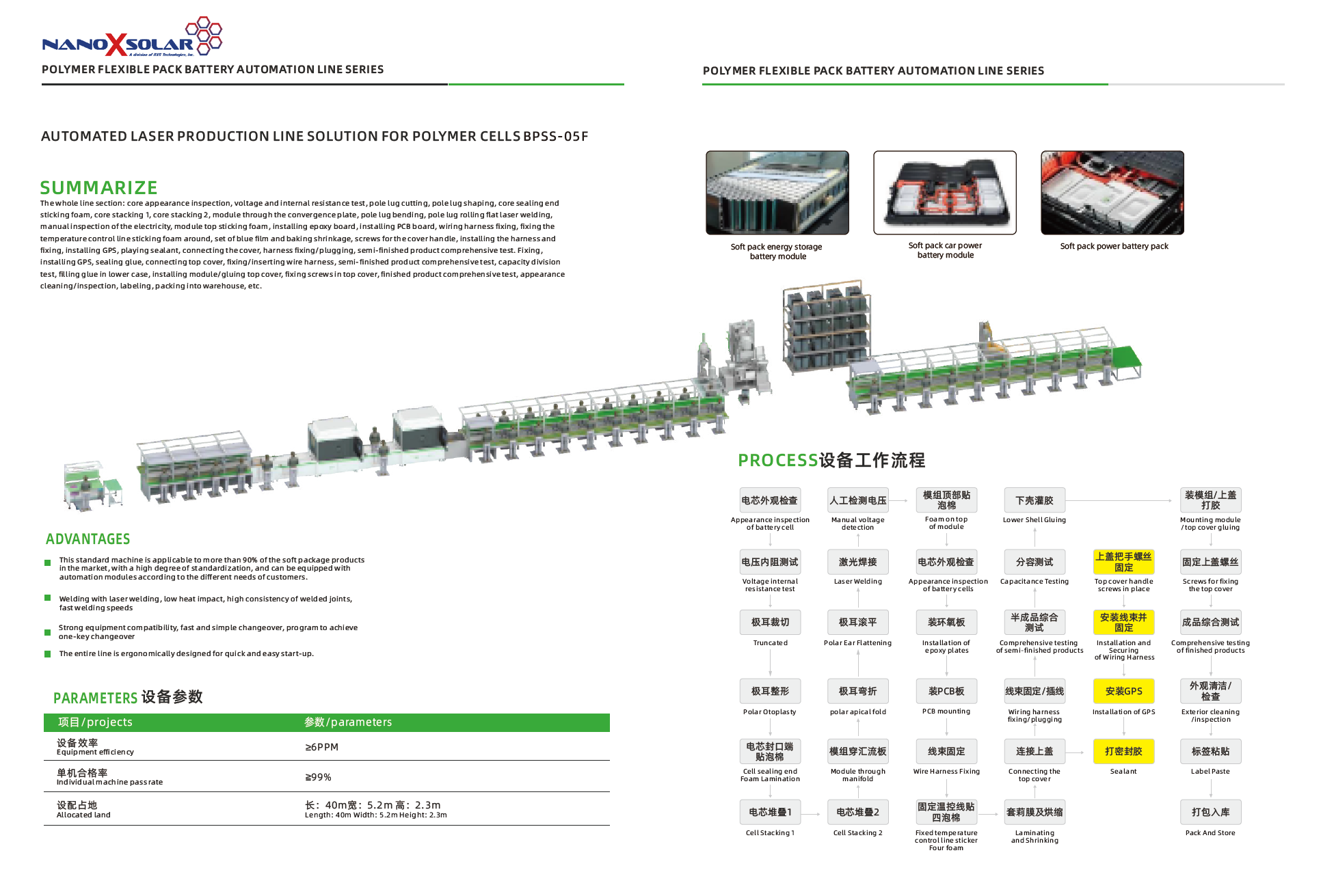

Battery Assembly Production Lines

Automated battery cell and pack assembly tooling lines

Advanced Battery Manufacturing Systems

Complete battery assembly production lines featuring semi-automated and fully automated systems for prismatic cells, pack assembly, and polymer cell manufacturing. Tier-1 equipment designed for high-volume production.

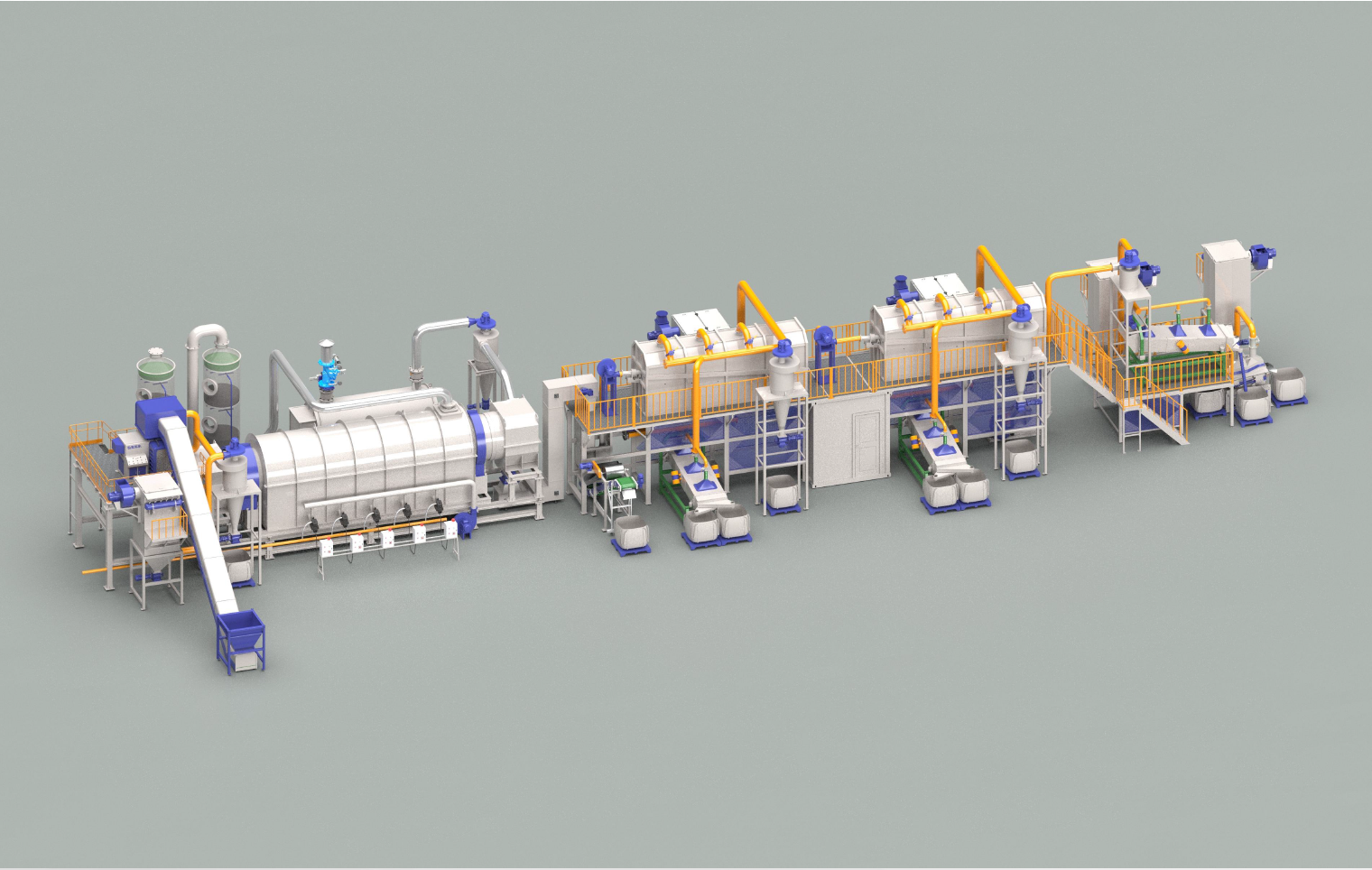

Request Production Line QuoteBattery Recycling Line

Anode/Cathode separation and black mass recovery

Advanced Black Mass Recovery

We offer tooling lines to recycle lithium batteries, recovering useful feedstocks from anodes, cathodes, and foils. Our process separates interlayer plastics (PP insulation) from the anode and cathode materials.

Process Specifications

- Particle size reduction to 500-600 mesh

- Crushing and cutting separates aluminum and copper foils

- Sieving to 80-120 mesh isolates black mass

- Fine powder collection (1-3mm optimal)

Recovered Materials

- Anode materials (graphite, silicon)

- Cathode materials (lithium compounds)

- Aluminum foil (cathode current collector)

- Copper foil (anode current collector)

- PP separator plastics

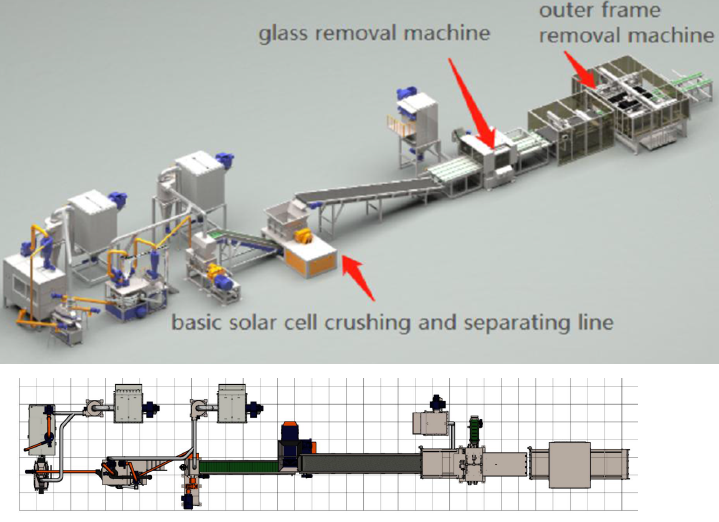

PV Recycling Line

Process 2000kgs per hour with Solar Panel Recycling Plant

Complete Solar Panel Recycling System

Process 2000kgs per hour with Solar Panel Recycling Plant. Solar Panel outer frame removing machine. Solar Panel Glass removing machine. Solar Panel Crushing and Separating equipment.

- Solar Panel outer frame removing machine

- Solar Panel Glass removing machine

- Solar Panel Crushing and Separating equipment