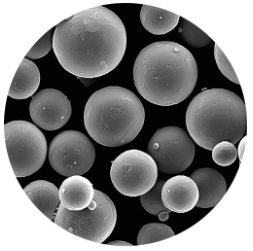

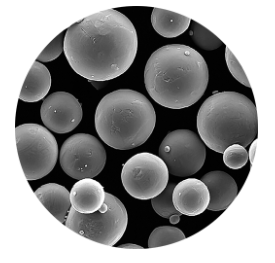

Nano-Powders to Spherical Powders

Nano-materials as raw feedstocks for battery cell feedstocks, industrial critical supply chain of nano powders. From 441 recycled mono-silicon to 11N (99.99999999999%) ultra high purity mono-silicon from silicon metal, CVD SIEMENS TCS/MONO Silane processing from SiO2 Quartzite. Hydrocarbons into CNT's and utilizing plasma MW torch for diamond like carbon nano-powders for cell materials.

Exceptional Capacity for Energy Storage

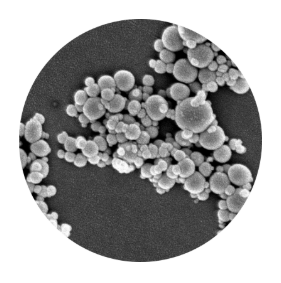

Our silicon nano-powder has a controlled nanoscale size and high purity level. These properties provide an impressive capacity of electric charge.

We use Mono-silicon nano-powders to help with ASSB generations of Lithium-ion batteries and Sodium ion cells. N6-Grade 441 recycled mono-silicon to 11N (99.99999999999%) ultra high purity mono-silicon from silicon metal, CVD SIEMENS TCS/MONO Silane processing from SiO2 Quartzite.

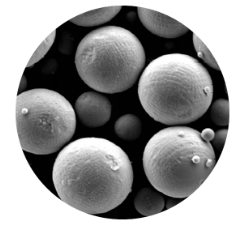

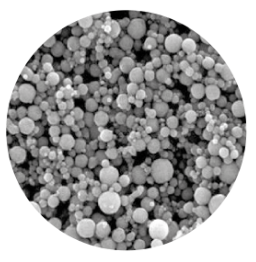

Highly Conductive Copper Nanopowder

The excellent electrical conductivity and narrow size distribution of NanoXSolar's copper nano-powders are ideal for the production of conductive printer ink and for the production of photovoltaic cells. They also have biocidal properties making them ideal for certain biomedical applications.

The exceptional level of purity of NanoXSolar copper nano-powders allows them to reach a compatible melting point with a wide range of substrates.

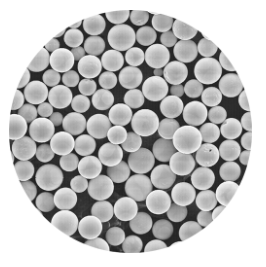

Advanced Applications

Ultra highly demanding in terms of materials quality. Nickel layers (used as electrodes interposed between dielectric layers) with thickness smaller than 400 nm (0.4 µm) must be made from paste containing Nickel nanoparticles that meets an exhaustive list of specifications, namely: a mean diameter of 80 nm or less, a spherical morphology, a controlled chemistry, and a very low level of agglomeration and super fine doped powder.