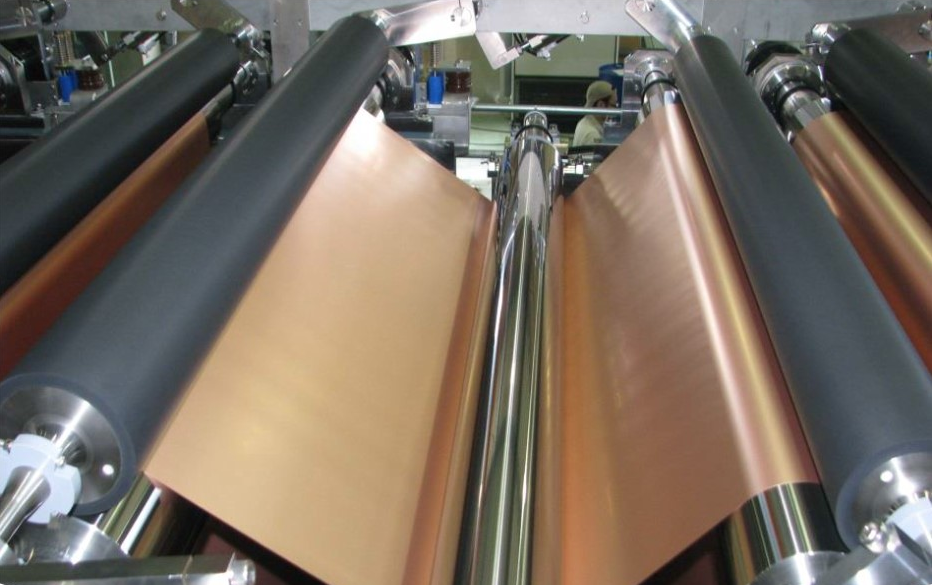

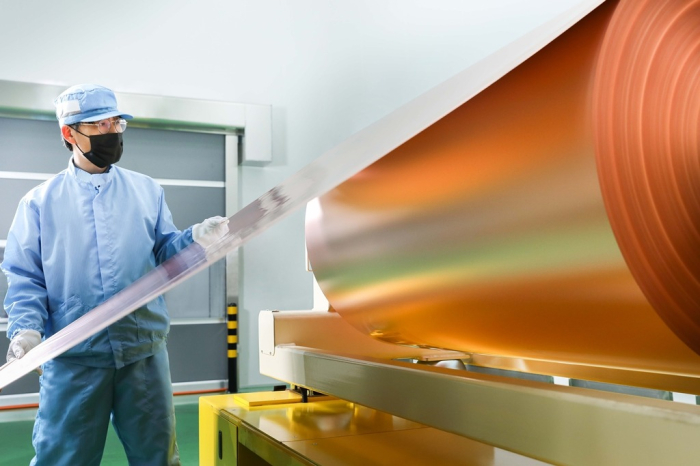

Precision-Engineered Metal Foils

Our battery-grade copper and aluminum foils are manufactured to exacting specifications, providing superior electrical conductivity and mechanical stability for lithium-ion battery current collectors.

Advanced Manufacturing Processes

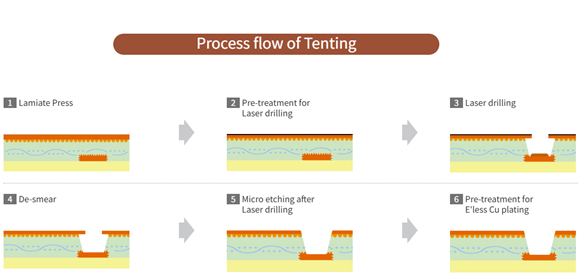

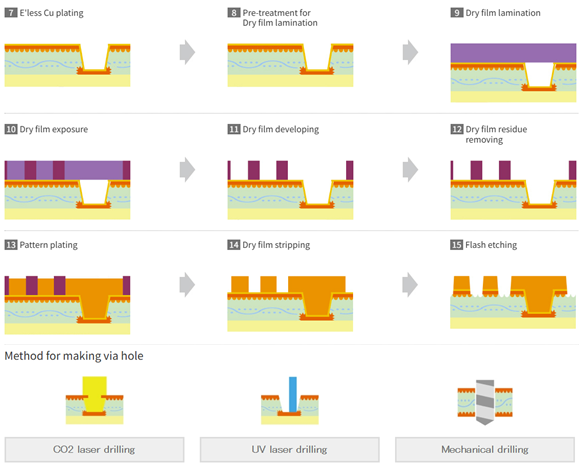

Tenting Process

Advanced photoresist tenting for precise pattern definition in circuit manufacturing.

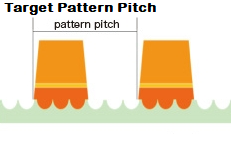

MSAP Process

Modified Semi-Additive Process for ultra-fine line circuits with superior precision.

SAP Process

Semi-Additive Process for high-density interconnect with minimal waste.

Copper Foil Specifications

Thickness Range:

6-35 μm

Purity:

≥99.8%

Surface Treatment:

Matte/Shiny

Application:

Anode Current Collector

Aluminum Foil Specifications

Thickness Range:

10-20 μm

Purity:

≥99.99%

Surface Treatment:

Anodized/Coated

Application:

Cathode Current Collector